ZRO2-II zirconia oxygen analyzer

Description

ZRO2-II zirconia oxygen analyzer is a modern commonly used instrument, suitable for all kinds of industrial boilers, kilns and heating furnace flue gas oxygen content measurement. ZrO2-II in-line oxygen analyzer is characterized by high sensitivity, excellent reproducibility and stability, automatic switching, fast response, wide range and continuous online measurement. It can realize low oxygen combustion control, achieve energy saving, reduce environmental pollution and improve environmental quality.

ZRO2-II Zirconia Oxygen analyzer Principle:

1, according to the concentration of the battery principle, and other batteries, it has two half batteries, and between the two electrodes, with solid dielectric zirconia connection.

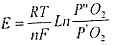

2, at high temperature, when the oxygen concentration difference on both sides of zirconia, oxygen concentration difference battery is formed, the size of the battery electromotive force can be calculated according to the Nernst formula, namely:

Where: E-concentration battery output, mV; n- the number of electron transfers, which in this case is 4;

R- ideal gas constant, 9.314 W*S/mol; F- Faraday constant, 96,500 C;

T- temperature,K; P"Q- high concentration side oxygen partial pressure; P 'Q - low concentration side oxygen partial pressure.

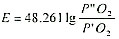

When the operating temperature of the battery is fixed at 700℃, the above formula is:

As can be seen from the above equation, when the temperature is 700℃, when the oxygen partial pressure of the solid dielectric side is air (20.6%), the electromotive force E is output by the concentration battery, and the oxygen partial pressure of the solid dielectric side can be calculated. This is the oxygen measurement principle of the automatic zirconia oxygen analyzer.

ZrO2-II in-line zirconia oxygen analyzer is stable and reliable in oxygen measurement, prolonging service life, improving the ability of self-diagnosis and anti-interference. This instrument has made obvious improvement in the following convenience:

1. The signal has the necessary self-diagnosis function.

2, with a variety of linear range options.

3. The temperature rise curve given by the instrument temperature control system can meet the requirement of the heating rate of zirconia material.

4. The chemical formula and production process of porous platinum electrode can ensure that the zirconia probe of oxygen detector has enough service life in the boiler smoke atmosphere.

ZRO2-II Zirconia Oxygen analyzer conditions:

1, the installation site of oxygen detector must meet the conditions:

Have enough work space;

Instrument to avoid vibration occasions;

The flue gas temperature and pressure should be within the scope specified by the instrument. (Flue gas temperature < 650℃)

2, signal converter needs to meet the conditions:

Ambient temperature: 0-50℃

Operating environment temperature: ≤90%

Power supply voltage: 220V.AC±10%Hz

Power consumption: 150W

No inflammable, explosive and corrosive gases, and good ventilation is required.

Technical parameters of ZRO2-II zirconia oxygen analyzer:

Detector length: 0.2m, 0.4m, 0.8m, 1.0m, 1.2m, 1.4m (can be customized according to requirements);

Measuring range: 0~25.0%;

Measurement accuracy: 3%;

Temperature accuracy: 700±1℃;

Output signal: 0-10mA or 4-20mA;

Response time: ≤5S (90% measured value);

Load resistance: 0-800Ω (4-20mA output), 0-1.6kΩ (0-10mA output);

Display: oxygen concentration (), oxygen potential (mV), furnace temperature (℃), heating voltage (V), range, lower limit (), upper, lower limit alarm ().

Keyboard setting: alarm upper and lower limit setting, probe zero potential correction.

Symbols of self-diagnosis content and fault category: Upper oxygen limit of E-0, lower oxygen limit of E-1, abnormal temperature of E-2 (high), abnormal temperature of E-3 (low), abnormal temperature of E-4 (fast), abnormal temperature of E-5 (stop), abnormal oxygen potential of E-6 and broken couple of E-7.

Message